Waste Heat Recovery based Organic Ranking Cycles

We are Leading Manufacturer, Supplier, Exporter of Waste Heat Recovery based Organic Ranking Cycles, Waste Heat Recovery ORC from Pune, Maharashtra, India.

- Opel Energy is known for Waste Heat Recovery Systems and Energy Conservation projects.

- For last 17 years from its inception, Opel has worked with many industries to help them save a huge amount of Energy, through simple, smooth & cost-effective solutions.

- Organic Rankine Cycle ( ORC ) to capture wasted heat and turn it into additional power.

- Heat can be recovered from a wide range of systems such as

- Reciprocating engines,

- Biomass boilers,

- Microturbines and

- Concentrated Solar Power Unit etc.

- The turbine drives a generator to convert the work into electricity. The remaining steam is then condensed and recycled as feed water to the boiler. Instead of water, an organic fluid can also be used.

- Fluids can be used below a temperature of 150°C to 75°C and do not need to be overheated.

- Any exhaust gas which is being emitted at a high temp.from source.

- This heat can be converted into either Hot Water Or Thermic Fluid which in turn can be used for driving the ORC Engine to generate power.

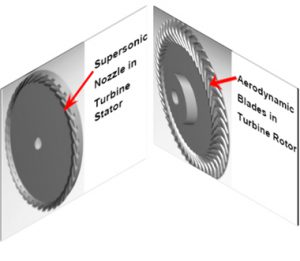

- Proved ORC with Lower Capacity with Lower Temperature. Due to the Compact arrangement of the Turbine, thermal losses are minimized and suitable to 150° to 75°. The Turbine blade has a constant untwisted profile along its length to provide uniform radial flow. High precision blades can, therefore, be obtained from low-cost manufacturing methods, and a simple and accurate aerodynamic analysis can be used for the design. In most cases, full admission can be used on all stages due to the radial arrangement, which puts the low volumetric flow stages at a small diameter.

Advantages :

- High-efficiency turbine.

- Good part load efficiency.

- Wide operating range is possible ( 10% - 100% load ).

- Simple and compact turbine design.

- Lower temperature and pressure, compared to conventional steam applications.

- Low demand for repair and maintenance.

- It can be work from the mini plant of a 10-KW system, 20KW, 50KW up to Megawatts.

- The system can be operated for 20-Years life period.